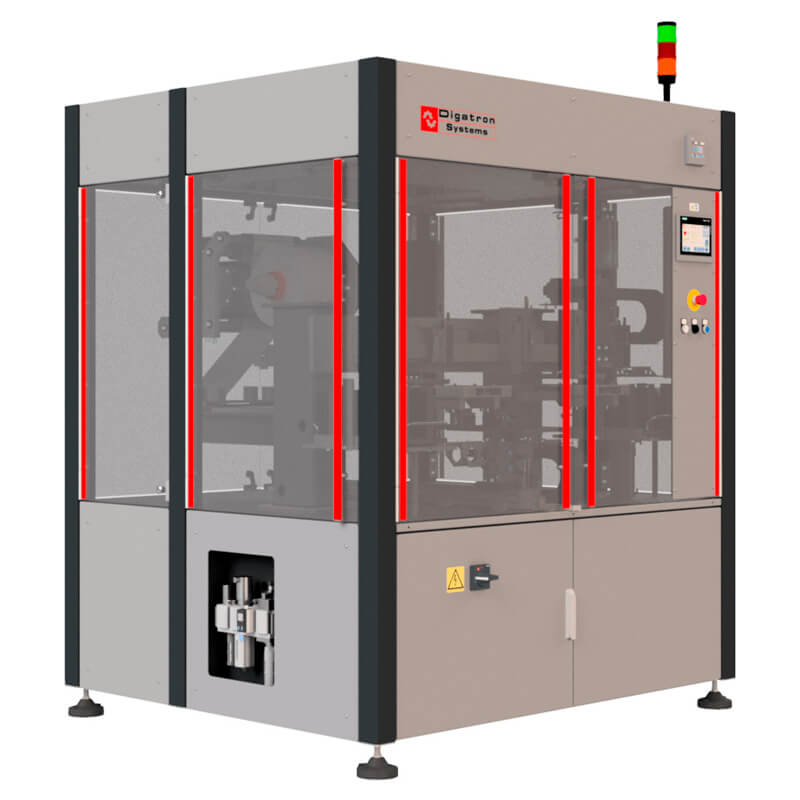

Sheet Stacking Unit (SSU)

SHEET STACKING UNIT

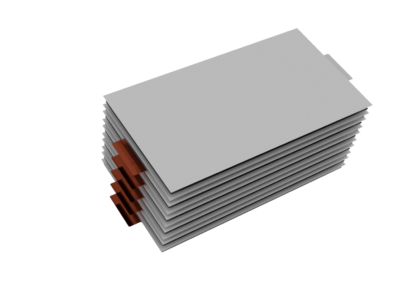

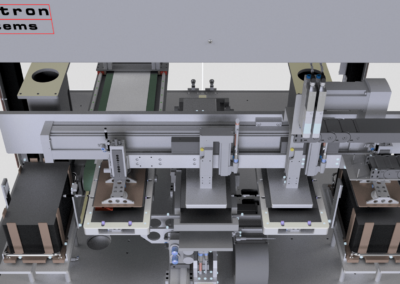

Digatron Systems SSU, Sheet Stacking Unit, is an automatic cell stacking machine, designed for the production of lithium cells. The operator manually loads the machine with one anode tray and one cathode tray and starts the automatic cycle. The electrodes are stored in specifically designed trays that bring them to the exact pick up level. Anode and cathode are automatically placed on an alignment system to ensure the correct position. A second pick and place unit then takes the electrodes and places them on the stacking head. The electrodes are held at a precise position while the stacking operation is performed. The separator is automatically unwound, kept at the correct tension and alignment by a dedicated system and then cut at the desired length. Separator sheet dimension can be adjusted by the operator on the machine HMI. Once stacking is completed the operator applies the sealing tape, removes the cell and starts a new stacking cycle.